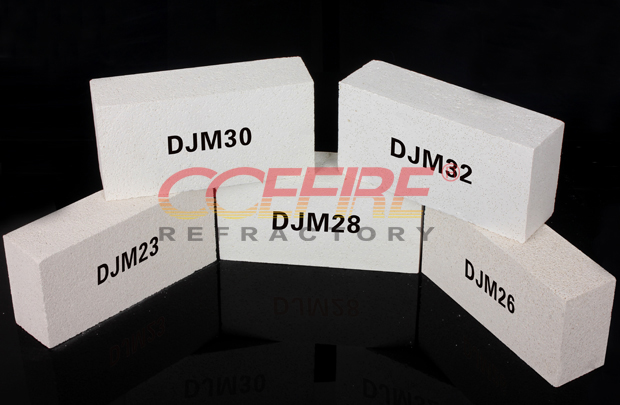

Mullite insulation brick is a new type of refractory material, which can directly contact with fire, characterized with high temperature resistance, lightweight, low thermal conductivity, good energy saving effect, specially suitable for cracking furnace, hot blast furnace, ceramic roller kiln, porcelain kiln extraction, glass crucible and various electric furnaces as lining. It is an ideal product of energy efficiency and longevity.

Strict control of raw materials

Control impurity content, ensure low thermal shrinkage, and improve heat resistance

Own large-scale ore base, professional mining equipment, and stricter selection of raw materials.

The incoming raw materials are tested first, and then the qualified raw materials are kept in a designated raw material warehouse to ensure their purity.

The raw materials of CCEFIRE insulation bricks have low impurity content with less than 1% oxides, such as iron and alkali metals. Therefore, CCEFIRE insulation bricks have high refractoriness, reaching 1760℃. The high aluminum content makes it maintain good performances in a reducing atmosphere.

Production process control

Reduce the content of slag balls, ensure low thermal conductivity, and improve thermal insulation performance

1. The fully automated batching system fully guarantees the stability of the raw material composition and better accuracy in raw material ratio.

2. With internationally advanced automated production lines of high-temp tunnel furnaces, shuttle furnaces, and rotary furnaces, the production processes from raw materials to finished products are under automatic computer-control, ensuring stable product quality.

3. Automated furnaces under stable temperature control produce CCEFIRE insulation bricks with thermal conductivity lower than 0.16w/m.k in an environment of 1000 ℃, and they have excellent thermal insulation performance, less than 05% in the permanent linear change, stable quality, and longer service life.

4. Accurate appearance size speeds up the bricks laying, saves the use of refractory mortar and also ensures the strength and stability of brickwork and extend the life of the furnace lining.

5. Can be processed into a special shape, in order to reduce the number of bricks and joints.

Quality control

Ensure bulk density and improve thermal insulation performance

1. Each shipment has a dedicated quality inspector, and a test report is provided prior to the departure of products from the factory to ensure the export quality of each shipment of CCEFIRE.

2. A third-party inspection (such as SGS, BV, etc.) is accepted.

3. Production is strictly in accordance with ASTM quality management system certification.

4. The outer packaging of each carton is made of five layers of kraft paper, and outer packaging + pallet,, suitable for long-distance transportation.

CCEFIRE insulation bricks have low thermal conductivity and good thermal insulation effects.

CCEFIRE insulation bricks have low thermal melting, and due to their low thermal conductivity, they accumulate very little heat energy, which leads to their remarkable energy-saving effects in intermittent operations.

CCCEFIRE thermal insulation bricks have low impurity content, especially very low in iron and alkali metal oxide content, so they have high refractoriness. Their high aluminum content allows them to maintain good performance in a reducing atmosphere.

CCEFIRE mullite insulation bricks have high thermal compressive strengths.

CCEFIRE thermal insulation bricks have accurate dimensions in appearance, which can speed up the construction speed, reduce the amount of refractory clay used, and ensure the strength and stability of the masonry, thereby extending the service life of the lining.

CCEFIRE mullite insulation brick can be processed into special shapes to reduce the number of bricks and joints.

Based on the above advantages, CCEFIRE insulation bricks and fiber ropes are widely used in hot blast furnace top, blast furnaces’ body and bottom, glass melting furnaces’ regenerator, ceramic sintering furnaces, dead corner furnace lining of petroleum cracking system, and the lining of ceramic roller furnaces, electric porcelain drawer furnaces , glass crucible and various electric furnaces.

-

Guatemalan Customer

Refractory Insulation Blanket - CCEWOOL®

Cooperation years: 7 years

Product size: 25×610×7620mm/ 38×610×5080mm/ 50×610×3810mm25-04-09 -

Singapore Customer

Refractory Ceramic Fiber Blanket - CCEWOOL®

Cooperation years: 3 years

Product size: 10x1100x15000mm25-04-02 -

Guatemala Customers

High Temp Ceramic Fiber Block - CCEWOOL®

Cooperation years: 7 years

Product size: 250x300x300mm25-03-26 -

Spanish Customer

Polycrystalline Fiber Modules - CCEWOOL®

Cooperation years: 7 years

Product size: 25x940x7320mm/ 25x280x7320mm25-03-19 -

Guatemala Customer

Ceramic Insulating Blanket - CCEWOOL®

Cooperation years: 7 years

Product size: 25x610x7320mm/ 38x610x5080mm/ 50x610x3810mm25-03-12 -

Portuguese customer

Refractory Ceramic Fibre Blanket - CCEWOOL®

Cooperation years: 3 years

Product size: 25x610x7320mm/50x610x3660mm25-03-05 -

Serbia customer

Refractory Ceramic Fiber Block - CCEWOOL®

Cooperation years: 6 years

Product size:200x300x300mm25-02-26 -

Italian customer

Refractory Fiber Modules - CCEWOOL®

Cooperation years: 5 years

Product size:300x300x300mm/300x300x350mm25-02-19