CCEWOOL ceramic fiber yarn has an excellent high-temp tensile strength.

CCEWOOL ceramic fiber yarn is reinforced by alkali-free glass fiber, resulting in a better high-temp insulation performance and a longer service life.

CCEWOOL ceramic fiber yarn is reinforced with steel wires, so it has a stronger resistance to high temperatures and a higher tensile strength.

CCEWOOL ceramic fiber yarn has a low thermal conductivity, low heat capacity, no asbestos and toxic, and it is harmless to the environment.

Based on the above advantages, the typical applications of CCEWOOL ceramic fiber yarn include:

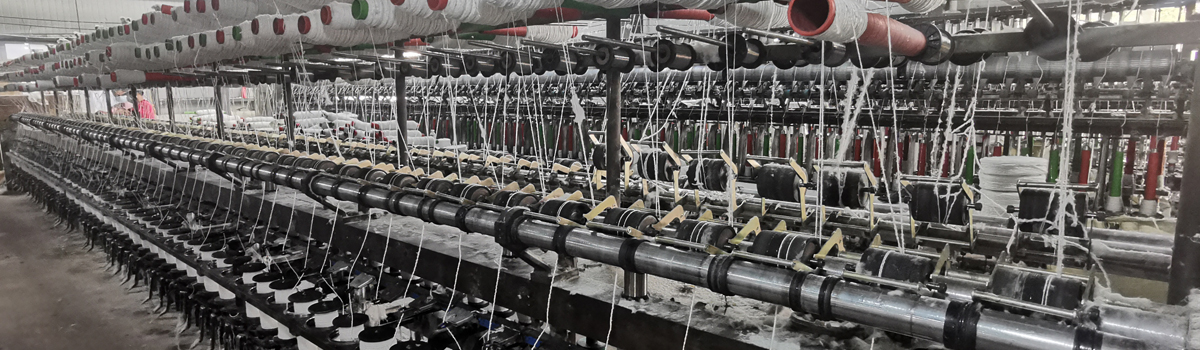

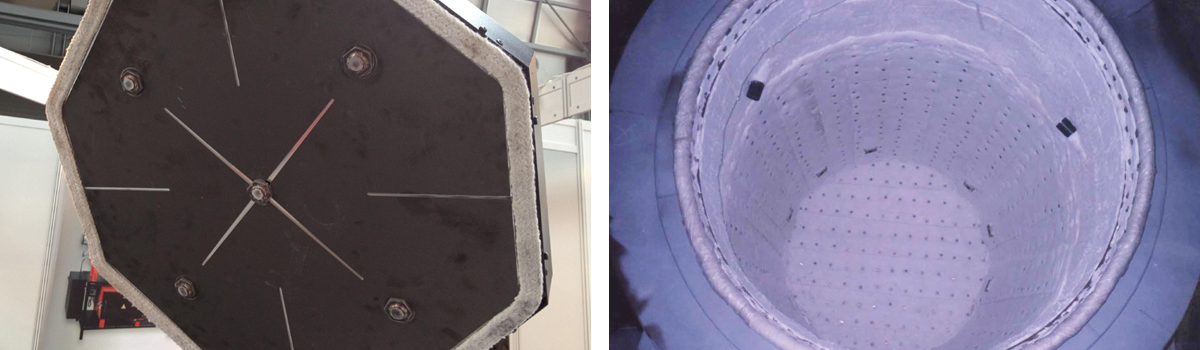

The processing of sewing threads for fireproof clothing, fireproof blankets, detachable insulation covers (bags/quilts/covers), etc.

The stitching threads for ceramic fiber blankets.

It can be used to sew ceramic fiber cloth, ceramic fiber tapes, ceramic fiber ropes and other high-temp resistant textiles, and it can also be used as high-temp sewing threads.