CCEWOOL soluble fiber tape has high-temp resistance, low thermal conductivity, thermal shock resistance, low heat capacity, excellent high-temp insulation performance, and a long service life.

CCEWOOL soluble fiber tape can resist the corrosion of non-ferrous metals, such as aluminum and zinc; it has good low-temp and high-temp strengths.

CCEWOOL soluble fiber tape is non-toxic, harmless, and has no adverse effects on the environment.

In view of the above advantages, the applications of CCEWOOL soluble fiber tape include:

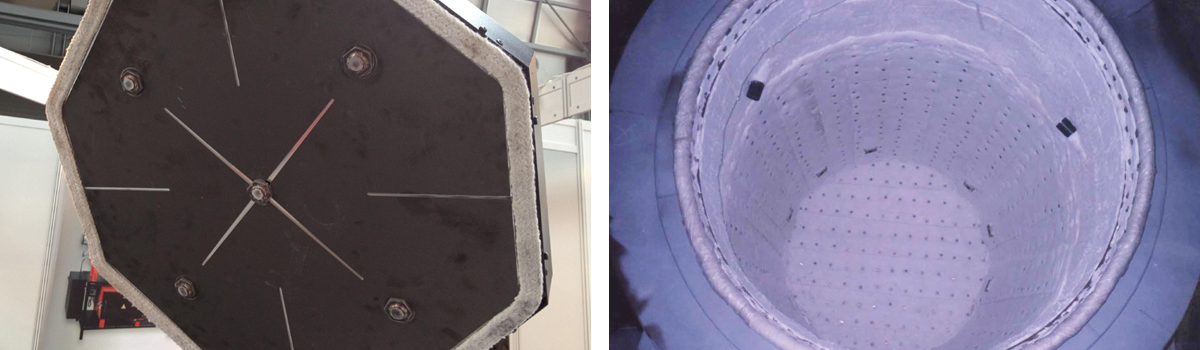

Thermal insulation on various furnaces, high-temp pipelines, and containers.

Furnace doors, valves, flange seals, materials of fire doors, fire shutter, or high-temp furnace door’s sensitive curtains.

Thermal insulation for engines and instruments, covering materials for fireproof cables, and high-temp fireproof materials.

Cloth for thermal insulation covering or high-temp expansion joint filler, and flue lining.

High-temp resistant labor protection products, fire protection clothing, high-temp filtration, sound absorption and other applications in replacement of asbestos.