Temperature degree: 1200℃

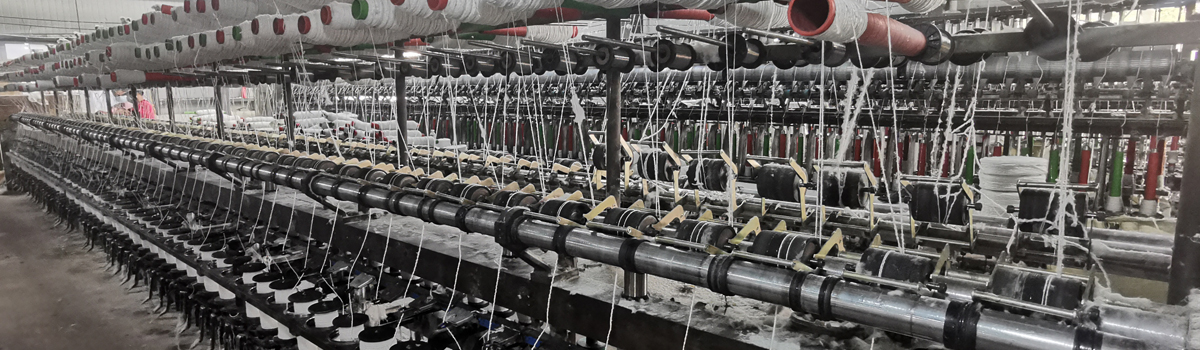

Bio-soluble ceramic fiber yarn is yarn-shape high-temperature products which composed of soluble fibers blended with certain percentage organic bulk, reinforced with fiberglass or inconel wire.

Temperature degree: 1200℃

Bio-soluble ceramic fiber yarn is yarn-shape high-temperature products which composed of soluble fibers blended with certain percentage organic bulk, reinforced with fiberglass or inconel wire.

Strict control of raw materials

Control impurity content, ensure low thermal shrinkage, and improve heat resistance

1. CCEWOOL soluble fiber yarn is woven from high-quality soluble fiber textile cotton.

2. Because of the supplements of MgO, CaO and other ingredients, CCEWOOL soluble fiber cotton can expand its viscosity range of fiber formation, enhance its fiber formation conditions, improve fiber formation rate and fiber flexibility, and reduce the content of slag balls, so, the slag ball content of CCEWOOL soluble fiber yarn produced is lower than 8%. The content of the slag ball is an important index that determines the thermal conductivity of the fiber, so CCEWOOL soluble fiber yarn has low thermal conductivity and excellent thermal insulation performance.

3. Controlling the impurity content of raw materials is an important step to ensure the heat resistance of ceramic fibers. The high impurity content will cause the coarsening of crystal grains and the increase of linear shrinkage, which is an important factor attributing to the deterioration of fiber performance and the reduction of service life.

4. Through strict control at every step, we reduced the impurity content of raw materials to less than 1%. The thermal shrinkage rate of CCEWOOL soluble fiber yarn is lower than 2% at 1000 ℃, and they have stable quality and longer service life.

Production process control

Reduce the content of slag balls, ensure low thermal conductivity, and improve thermal insulation performance

1. The kind of organic fiber determines the flexibility of the soluble fiber cloth. CCEWOOL soluble fiber yarn uses organic fiber viscose with stronger flexibility.

2. CCEWOOL soluble fiber yarn is made by adding alkali-free glass filament and high-temp resistant stainless-steel alloy wires through a special process. Therefore, it has good resistance to acid and alkali corrosion as well as molten metals, such as aluminum and zinc.

Quality control

Ensure bulk density and improve thermal insulation performance

1. Each shipment has a dedicated quality inspector, and a test report is provided prior to the departure of products from the factory to ensure the export quality of each shipment of CCEWOOL.

2. A third-party inspection (such as SGS, BV, etc.) is accepted.

3. Production is strictly in accordance with ISO9000 quality management system certification.

4. Products are weighed before packaging to ensure that the actual weight of a single roll is greater than the theoretical weight.

5. The outer packaging of each carton is made of five layers of kraft paper, and the inner packaging is a plastic bag, suitable for long-distance transportation.

CCEWOOL soluble fiber yarn has an excellent high-temp tensile strength.

CCEWOOL soluble fiber yarn is reinforced by alkali-free glass fiber, resulting in a better high-temp insulation performance and a longer service life.

CCEWOOL soluble fiber yarn is reinforced with steel wires, so it has a stronger resistance to high temperatures and a higher tensile strength.

CCEWOOL soluble fiber yarn has a low thermal conductivity, low heat capacity, no asbestos and toxic, and it is harmless to the environment.

Based on the above advantages, the typical applications of CCEWOOL soluble fiber yarn include:

The processing of sewing threads for fireproof clothing, fireproof blankets, detachable insulation covers (bags/quilts/covers), etc.

The stitching threads for ceramic fiber blankets.

It can be used to sew soluble fiber cloth, soluble fiber tapes, soluble fiber ropes and other high-temp resistant textiles, and it can also be used as high-temp sewing threads.

Refractory Insulation Blanket - CCEWOOL®

Cooperation years: 7 years

Product size: 25×610×7620mm/ 38×610×5080mm/ 50×610×3810mm

Refractory Ceramic Fiber Blanket - CCEWOOL®

Cooperation years: 3 years

Product size: 10x1100x15000mm

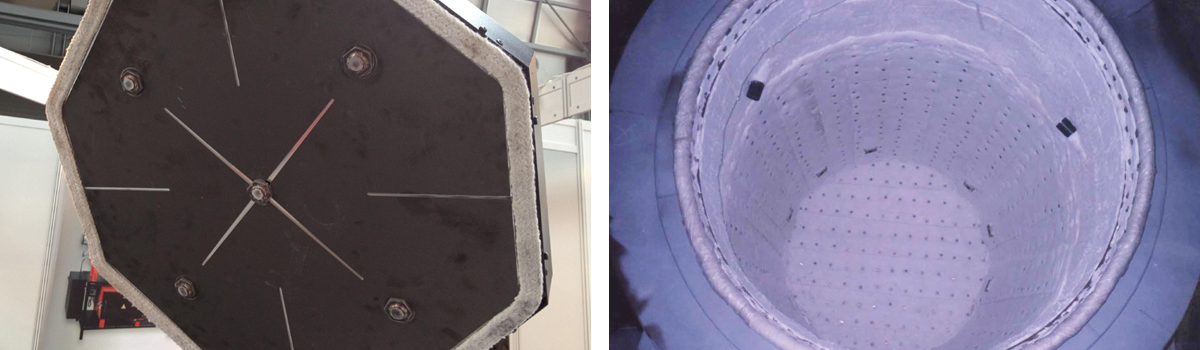

High Temp Ceramic Fiber Block - CCEWOOL®

Cooperation years: 7 years

Product size: 250x300x300mm

Polycrystalline Fiber Modules - CCEWOOL®

Cooperation years: 7 years

Product size: 25x940x7320mm/ 25x280x7320mm

Ceramic Insulating Blanket - CCEWOOL®

Cooperation years: 7 years

Product size: 25x610x7320mm/ 38x610x5080mm/ 50x610x3810mm

Refractory Ceramic Fibre Blanket - CCEWOOL®

Cooperation years: 3 years

Product size: 25x610x7320mm/50x610x3660mm

Refractory Ceramic Fiber Block - CCEWOOL®

Cooperation years: 6 years

Product size:200x300x300mm

Refractory Fiber Modules - CCEWOOL®

Cooperation years: 5 years

Product size:300x300x300mm/300x300x350mm