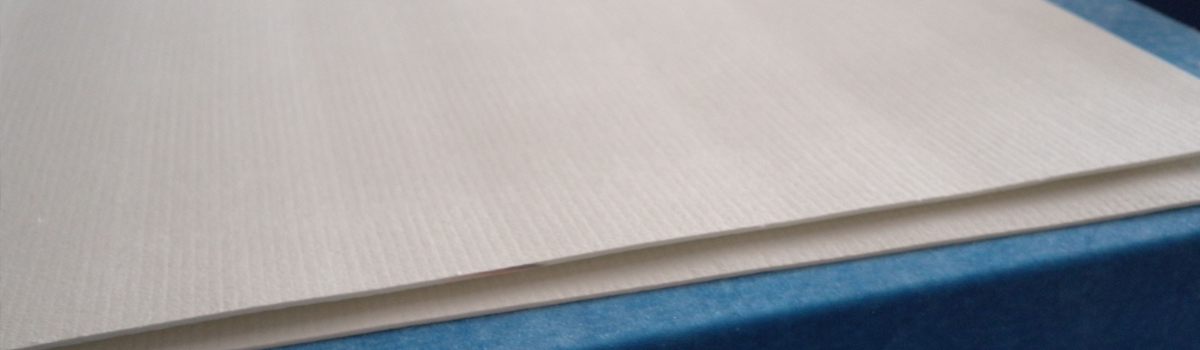

Temperature degree: 1050℃ (1922℉), 1260℃ (2300℉), 1400℃ (2550℉), 1430℃(2600℉)

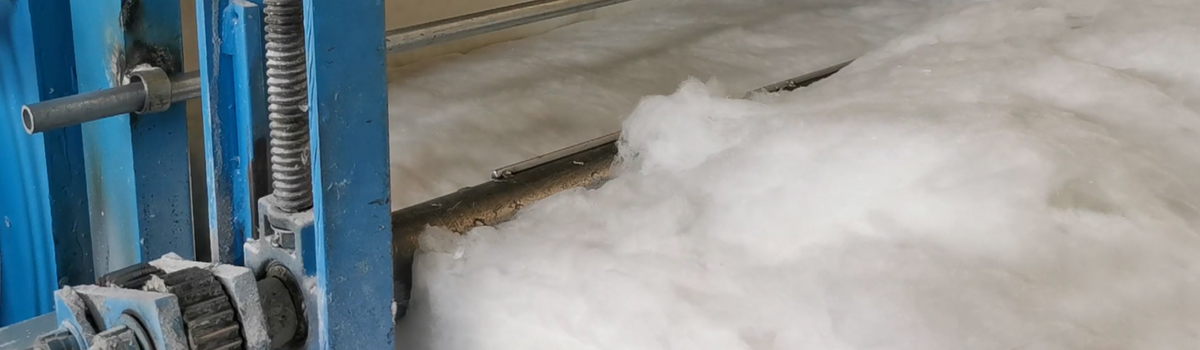

CCEWOOL® Research series ultra-thin ceramic fiber board’s thickness range is from 5 to 10mm. Manufactured from automatic production line provides it with precise thickness and high compressive strength. It is widely used in electrical appliance and electronic equipment.