Temperature range: 1260℃ (2300℉) - 1430℃(2600℉)

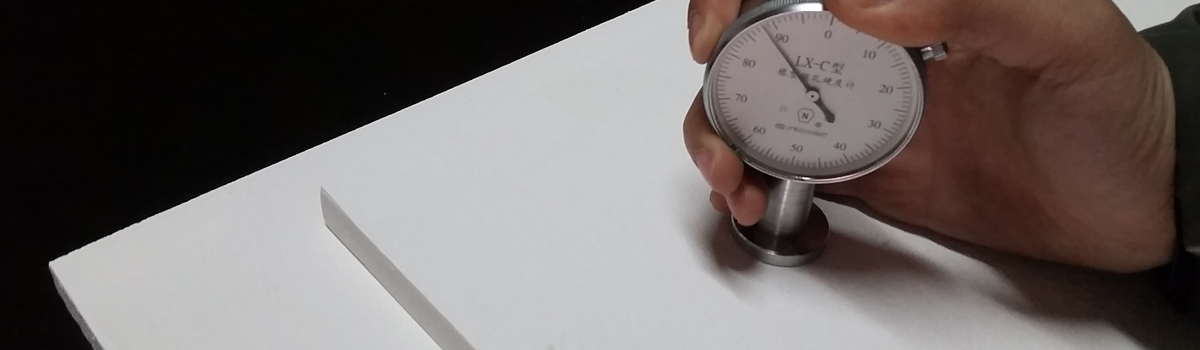

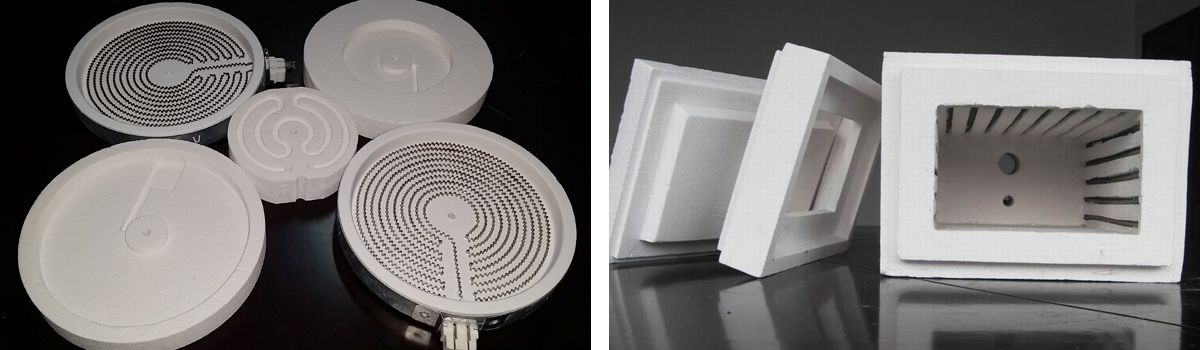

CCEWOOL® Unshaped Vacuum Formed Ceramic Fiber shapes is made from high quality ceramic fiber bulk as raw material, through vacuum forming process. This product is developed into unshaped product with both superior high-temperature rigidity and self-supporting strength. We produce CCEWOOL® Unshaped Vacuum Formed Ceramic Fiber to fit for the demand for some specific industrial sector production processes. Depending on performance requirements of the unshaped products, different binders and additives are used in production process. All unshaped products are subject to relatively low shrinkage in their temperature ranges, and maintain a high thermal insulation, lightweight and shock resistance. The non-burnt material can easily be cut or machined. During use, this product shows excellent resistance to abrasion and stripping, and can not be wetted by most molten metals.