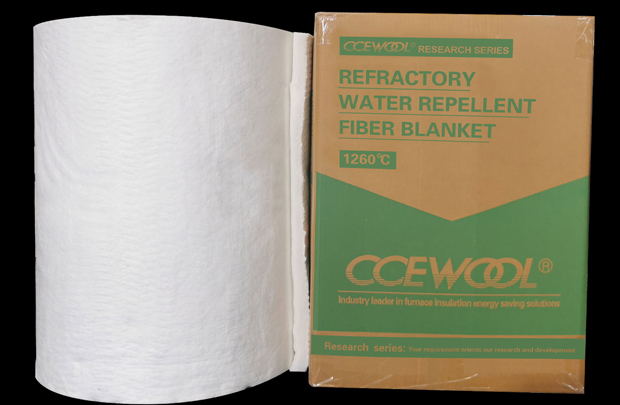

CCEWOOL® research series water repellent ceramic fiber blanket is needled blanket with super high tensile strength which is made from spun ceramic fiber bulk. It is produced with unique inside double needle technology with solvent-based high-temperature nano-hydrophobic material as the surface treatment agent, and has the characteristics of excellent overall hydrophobicity which greatly improved the insulation performance of the fiber blanket and solved the problem of decreasing of thermal insulation performance and corrosion of insulated object caused by moisture absorption of conventional fiber blankets.

Strict control of raw materials

Control impurity content, ensure low thermal shrinkage, and improve heat resistance

Self owned raw material base, material inspection before entering factory, computer-controlled ingredient proportion system, minimize the impurity content of the raw materials. So CCEWOOL ceramic fiber blanket is whiter and has lower heat shrinkage at high temperatures, longer service life, and more stable quality.

Production process control

Reduce the content of slag balls, ensure low thermal conductivity, and improve thermal insulation performance

1. The fully automated batching system fully guarantees the stability of the raw material composition and improves the accuracy of raw material ratio.

2. With an imported high-speed centrifuge of which the speed reaches up to 11000r/min, the fiber forming rate becomes higher. The thickness of CCEWOOL ceramic fiber is uniform, and the content of slag ball is lower than 10%. The slag ball content is an important index that determines the thermal conductivity of fiber. The thermal conductivity of CCEWOOL ceramic fiber Water-repellent blanket is lower than 0.28w/m.k in a high-temp environment of 1000°C, so they have an excellent thermal insulation performance.

3. The condenser spreads cotton evenly to ensure the uniform density of CCEWOOL ceramic fiber Water-repellent blankets.

4. The use of the self-innovated double-sided inner- needle-flower punching process and the daily replacement of the needle punching panel ensure the even distribution of the needle punch pattern, which allows the tensile strength of CCEWOOL ceramic fiber Water-repellent blankets to exceed 70Kpa and the product quality to become more stable.

5. CCEWOOL ceramic fiber water-repellent blankets use solvent-based high-temp nano-hydrophobic material as the surface treatment agent, reaching a water-repellent rate of over 99%, which realizes the overall water-repellency of the ceramic fiber blankets and solves the issue of the decrease in thermal conductivity caused by moisture absorption of conventional fiber blankets.

Quality control

Ensure bulk density and improve thermal insulation performance

1. Each shipment has a dedicated quality inspector, and a test report is provided prior to the departure of products from the factory to ensure the export quality of each shipment of CCEWOOL.

2. A third-party inspection (such as SGS, BV, etc.) is accepted.

3. Production is strictly in accordance with ISO9000 quality management system certification.

4. Products are weighed before packaging to ensure that the actual weight of a single roll is greater than the theoretical weight.

5. The outer packaging of each carton is made of five layers of kraft paper, and the inner packaging is a plastic bag, suitable for long-distance transportation.

Insulation

The excellent water repellency, heat preservation, and resistance to oil, liquid, and spark of CCEWOOL ceramic fiber water-repellent blankets make them a thermal insulation material in a wide range of environments.

They are mainly used for heat insulation on pipes, boilers, storage tanks or other system components to prevent energy loss and solve the safety problems of workers.

Cold protection

CCEWOOL ceramic fiber water-repellent blankets can effectively prevent energy waste from the refrigeration pipeline due to its contact with the external heat sources and thereby, warm the pipeline up.

The huge difference between the temperatures of the refrigerated pipeline and the ambient temperature can cause water to condense on the pipeline. However, CCEWOOL ceramic fiber water-repellent blankets can prevent condensation on the pipeline; therefore, they help prevent corrosion and protect the corresponding production components and the safety of the staff.

Fire prevention

A fire in an industrial plant can cause catastrophic consequences including property damage and even a threat to life. However, CEWOOL ceramic fiber water-repellent blankets can resist fire at temperatures up to 1400°C for up to 2 hours, which can minimize the danger and damage caused by fires in oil refineries, oil platforms, petrochemicals, thermal power generation, power, shipbuilding, and national defense plants.

Noise reduction

Continuous background noise affects the efficiency of working environments and the quality of life in the long run.

Because of the high-quality sound-absorbing and water-repellent properties, CCEWOOL ceramic fiber water-repellent blankets can effectively eliminate noise, prevent moisture, and increase service life.

CCEWOOL ceramic fiber water-repellent blankets’ application areas include:

Sheathed steel beams and ventilation ducts

Installation of firewalls, doors, and ceilings

Insulation of cables and wires in wall pipes

Fire protection of ship decks and bulkheads

Soundproof enclosure and measuring room

Sound insulation in industries and power plants

Noise barrier

Sound insulation in construction

Sound insulation of ships and cars

-

Italian customer

1260℃ Ceramic Fiber Bulk - CCEWOOL®

Cooperation years: 2 years25-06-25 -

Polish Customer

Thermal Insulation Blanket - CCEWOOL®

Cooperation years: 6 years

Product size: 19×610×9760mm/ 50×610×3810mm25-04-30 -

Spanish Customer

Ceramic Fiber Insulation Roll - CCEWOOL®

Cooperation years: 7 years

Product size: 25×940×7320mm/ 25×280×7320mm25-04-23 -

Peruvian Customer

Refractory Ceramic Fiber Blanket - CCEWOOL®

Cooperation years: 6 years

Product size: 25×610×7620mm/ 50×610×3810mm25-04-16 -

Guatemalan Customer

Refractory Insulation Blanket - CCEWOOL®

Cooperation years: 7 years

Product size: 25×610×7620mm/ 38×610×5080mm/ 50×610×3810mm25-04-09 -

Singapore Customer

Refractory Ceramic Fiber Blanket - CCEWOOL®

Cooperation years: 3 years

Product size: 10x1100x15000mm25-04-02 -

Guatemala Customers

High Temp Ceramic Fiber Block - CCEWOOL®

Cooperation years: 7 years

Product size: 250x300x300mm25-03-26 -

Spanish Customer

Polycrystalline Fiber Modules - CCEWOOL®

Cooperation years: 7 years

Product size: 25x940x7320mm/ 25x280x7320mm25-03-19