Ceramic fiber products have good thermal insulation effect and good comprehensive performance.

The use of refractory ceramic fiber products instead of asbestos boards and bricks as the lining and thermal insulation material of glass annealing equipment has many advantages. This issue we will continue to introduce its other advantages:

4. Small pieces can be bonded into big pieces which can reduce the waste of sheared edges and further reduce the cost of equipment.

5. Reduce the weight of the equipment, simplify the structure, reduce the structural material, reduce the cost and prolong the service life.

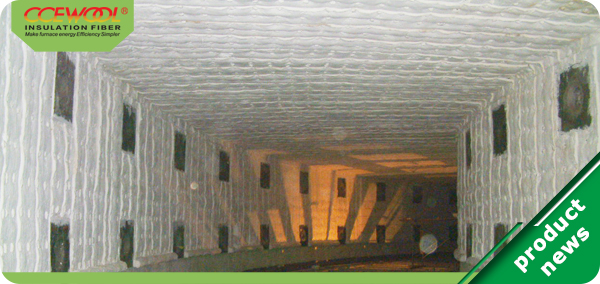

6. There are many varieties of ceramic fiber products, such as soft felt, hard felt, board, gasket, etc. Special products can be customized. It can be used for masonry or being pasted on the exterior brick wall as insulation lining. It can also be filled in the metal and brick interlayer to improve the thermal insulation effect. It is easy to operate, saves labor and materials, and has less investment. It is a new type of refractory insulation material with low price and good quality. Ceramic fiber products are used in various industrial furnace linings. Under the same production conditions, furnaces with ceramic fiber products linings can generally save 25~35% of energy compared with furnaces with brick linings. Therefore, it will be very promising to introduce ceramic fiber products into the glass industry and apply them to glass annealing equipment as lining or thermal insulation layer materials.

Post time: Aug-08-2022