Ceramic fiber blanket insulation is a type of high-temperature insulation material that is commonly used in industrial applications. It is made from high-purity alumina-silica fibers, are derived from raw materials like kaolin clay or aluminum silicate.

The composition of ceramic fiber blankets can vary, but they generally consist of around 50-70% alumina (Al2O) and 30-50% silica (SiO2). These materials provide the blanket with excellent thermal insulation properties, as alumina has a high melting point and low thermal conductivity, while silica has good thermal stability and resistance to heat.

Ceramic fiber blanket insulation also has other properties. It is highly resistant to thermal shock, meaning it can withstand rapid changes in temperature cracking or degrading. Additionally, it has low heat storage capabilities, allowing it to quickly cool down once the heat source is removed.

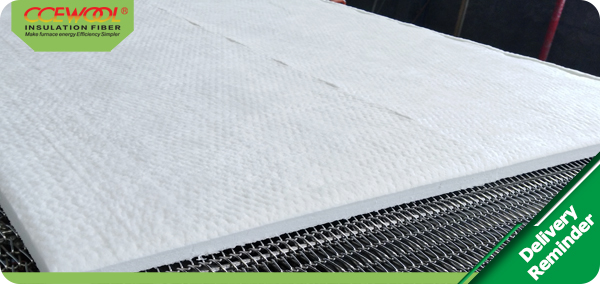

The manufacturing process of ceramic fiber blanket insulation produces a material is lightweight and flexible, making it easy to handle and install. It can be easily cut to specific dimensions and can conform to irregular surfaces and shapes.

Overall, ceramic fiber blanket insulation is a superior choice for high-temperature environments due to its excellent thermal insulation properties and ability to withstand extreme. Whether it is used in furnaces, kilns, or other industrial applications, ceramic fiber insulation provides a reliable solution for controlling heat transfer and improving energy efficiency.

Post time: Nov-29-2023