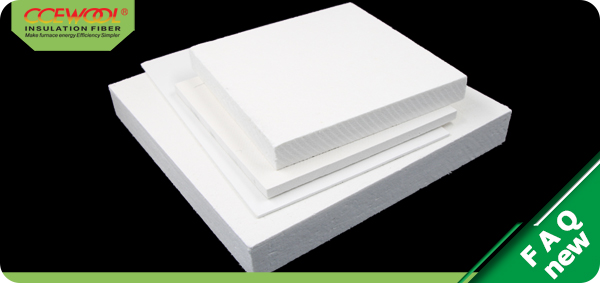

In high-temperature industrial environments, ceramic fiber boards are essential insulation materials, with their performance directly impacting the thermal efficiency and safety of equipment. The 1260°C ceramic fiber board, known for its outstanding high-temperature performance and excellent thermal insulation properties, is widely used in applications such as furnace linings and high-temperature pipe insulation, becoming the preferred insulation material in many industries.

The core components of CCEWOOL® 1260°C ceramic fiber board include alumina (Al₂O₃) and silica (SiO₂). The optimized ratio of these components provides the blanket with exceptional high-temperature performance and insulation capacity:

·Alumina (Al₂O₃): Alumina is a key component of the ceramic fiber board, significantly improving the material’s mechanical strength and thermal stability. In high-temperature environments, alumina enhances the fiber's heat resistance, ensuring it performs excellently at temperatures up to 1260°C without structural degradation or performance decline.

·Silica (SiO₂): Silica contributes to the excellent insulation properties of the ceramic fiber board. Due to its low thermal conductivity, silica effectively reduces heat transfer, improving the material's thermal insulation effect. Additionally, silica enhances the chemical stability of the ceramic fiber, making it more reliable in complex industrial environments.

Through the optimized ratio of alumina and silica, the 1260°C ceramic fiber board maintains superior performance even at extremely high temperatures, making it suitable for various high-temperature industrial applications.

CCEWOOL® 1260°C ceramic fiber board is manufactured using advanced production techniques, ensuring each batch of products delivers high-purity and high-quality raw materials. CCEWOOL® implements strict control in the following areas to guarantee product performance:

·Proprietary Raw Material Base: CCEWOOL® owns its own mining base and advanced mining equipment, ensuring that the raw materials used are carefully selected, guaranteeing high material quality from the source.

·Strict Raw Material Testing: All raw materials undergo rigorous chemical analysis and testing to meet high-quality standards. Each batch of qualified raw materials is stored in dedicated warehouses to maintain high purity and stability.

·Impurity Content Control: CCEWOOL® ensures that impurity levels in the raw materials are kept below 1%, guaranteeing the high performance of the ceramic fiber board from the source.

With the scientifically optimized composition and stringent manufacturing processes, CCEWOOL® 1260°C ceramic fiber board offers the following significant advantages:

·Outstanding High-Temperature Performance: The inclusion of alumina enhances the thermal stability of the ceramic fiber board, allowing it to operate stably in high-temperature environments up to 1260°C while maintaining excellent insulation performance.

·Excellent Thermal Insulation: Silica’s superior insulation properties effectively reduce heat transfer, significantly decreasing heat energy loss, improving energy utilization efficiency, and ensuring the efficient operation of equipment.

·High Mechanical Strength and Durability: Alumina enhances the mechanical strength of the fibers, enabling the 1260°C ceramic fiber board to withstand substantial external forces without damage, meeting the long-term usage requirements in complex industrial environments.

·Excellent Thermal Shock Resistance: The ceramic fiber board can withstand temperature fluctuations in high-temperature environments, preventing performance degradation due to thermal shock and maintaining stability under extreme temperature changes.

The CCEWOOL® 1260°C ceramic fiber board, with its optimized alumina and silica composition, delivers exceptional high-temperature performance and thermal insulation effects. With strict quality control, this ceramic fiber board remains stable and reliable in extreme high-temperature environments up to 1260°C, providing dependable thermal protection for furnace linings, pipeline insulation, and other high-temperature industrial equipment. Choose CCEWOOL® 1260°C ceramic fiber board for a long-lasting and stable insulation solution for your high-temperature applications, helping to improve energy efficiency, reduce energy consumption, and ensure the efficient, stable operation of equipment.

Post time: Feb-17-2025