Design and Construction of cracking furnaces

Overview:

The cracking furnace is a key equipment to large-scale ethylene production, which uses gaseous hydrocarbons (ethane, propane, butane) and liquid hydrocarbons (light oil, diesel, vacuum diesel) as raw materials. They, at the temperature of 750-900, are thermally cracked to produce petrochemical raw materials, such as ethane, propane, butadiene, acetylene and aromatics. There are two types of the cracking furnace: the light diesel cracking furnace and the ethane cracking furnace, both of which are a vertical type of heating furnaces. The furnace structure generally consists of two parts: the upper part is the convection section, and the lower part is the radiant section. The vertical furnace tube in the radiant section is the reaction part for the hydrocarbon heating of the cracking medium. The furnace temperature is 1260°C, and the walls on both sides and the bottom are equipped with oil and gas burners. In view of the above characteristics of the cracking furnace, the fiber lining is generally only used for the walls and the top of the radiant chamber.

Determining lining materials:

Considering the high furnace temperature (usually about 1260℃) and a weak reducing atmosphere in the cracking furnace as well as our years of design and construction experience and the fact that a large number of cracking furnace burners are generally distributed in the furnace at the bottom and on both sides of the wall, the lining material of the cracking furnace is determined to include a 4m high light-brick lining. The remaining parts use zirconium-containing fiber components as hot surface materials for the lining, while the back lining materials use CCEWOOL high aluminum (high purity) ceramic fiber blankets.

Lining structure:

Considering the large number of burners in the cracking furnace and the characteristics of the vertical box-type heating furnace in structure and based on our many years of design and construction experience, the furnace top adopts the structure of two layers of CCEWOOL high aluminum (or high purity) ceramic fiber blankets + central hole hoisting fiber components. The fiber components can be installed and fixed firmly in an angle iron or plug-in fiber component structure on the furnace walls, and the construction is quick and convenient as well as the disassemble and assemble during maintenance. The fiber lining has good integrity, and the heat insulation performance is remarkable.

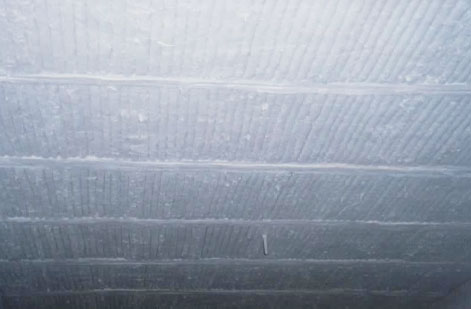

The form of fiber lining installation arrangement:

Based on the structural characteristics of the anchoring structure of the fiber components, the central hole hoisting fiber components on the top of the furnace adopt a "parquet floor" arrangement. The angle iron or plug-in fiber components on the furnace walls are arranged in the same direction sequentially along the folding direction. Fiber blankets of the same material in different rows are folded into a U shape to compensate for fiber shrinkage.

Post time: May-10-2021