Uyilo lweceramic fibre thermal insulation renovation of the boxes insulation in ingots' (i-slab (i-ingot yentsimbi)) iimoto zokuhambisa ezishushu.

Ukwaziswa kweebhokisi zokugquma kwii-ingots' (i-slab (i-ingot yentsimbi)) iimoto zokuhambisa ezishushu:

Ngenxa yenkqubo yemveliso enzima yamashishini esinyithi, ukuthuthwa kwamacwecwe (ii-ingots zentsimbi) phakathi kwe-sleb (i-ingot yentsimbi) ukunyibilikisa kunye nokuqengqeleka kweenkqubo zokuyila kunciphisa kakhulu iindleko zemveliso. Ukuze kuncitshiswe ukusetyenziswa kwamandla kumlinganiselo omkhulu kunye nokufezekisa injongo yokunciphisa iindleko zokuvelisa, amaninzi amashishini okuvelisa i-metallurgical asebenzisa i-slab (i-steel ingot) ukuhanjiswa okushushu (ekwabizwa ngokuba yi-slab okanye i-ingot ye-ingot i-red-hot delivery) izithuthi. Ngaphantsi kweemeko ezinjalo, ukugcinwa kobushushu kwebhokisi yezothutho kube yinto ebaluleke kakhulu.

Iimfuno zenkqubo yesakhiwo se-lining yebhokisi ye-insulation ye-automobile yezothutho ngokubanzi ibandakanya le miba ilandelayo: okokuqala, umsebenzi wexesha elide phantsi kobushushu obuphezulu be-1000 ℃, ukusebenza kakuhle kwe-insulation, kunye nokumelana nokutshatyalaliswa kwe-thermal kufuneka kuqinisekiswe; okwesibini, ukulayishwa kunye nokulayishwa kwe-slabs eshushu (i-ingots yentsimbi) ukunyuswa kufuneka kube lula, enokumelana nokugungqa, iimpembelelo, iimpumlo; kwaye okokugqibela, iibhokisi zokugquma kufuneka zibe nesakhiwo esikhanyayo, ubomi benkonzo ende, kunye neendleko eziphantsi.

Ukungalungi komgca wezitena ezikhanyayo: izitena ezikhanyayo zinokumelana nokutshatyalaliswa kwe-thermal, kwaye zivame ukutshatyalaliswa komonakalo ngexesha lokungcangcazela kwexesha elide, iimpembelelo kunye namaqhuma.

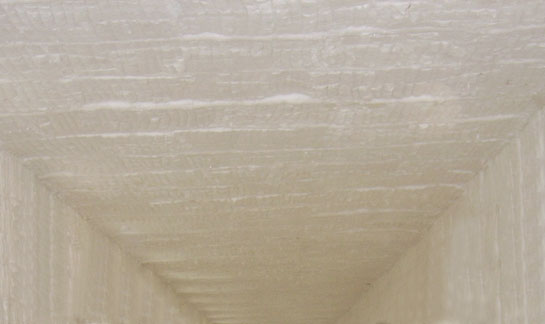

Uphuhliso kunye nokuphuculwa kweteknoloji yefiber ye-ceramic ibonelela ngesiseko esithembekileyo soyilo lweebhokisi zokugquma iimoto. I-CCEWOOL ye-ceramic fiber ilula, iguquguquka, iyamelana nobushushu obuphezulu kunye nokudinwa kwe-thermal, kwaye inokufunxa ukungcangcazela. Ngethuba nje ukwakhiwa kwesakhiwo kunengqiqo, umgangatho wokwakha unokufumaneka, kwaye iimfuno zenkqubo engentla zinokufezekiswa ngokupheleleyo. Ngoko ke, ukusetyenziswa kwe-CCEWOOL ye-ceramic fiber njengesakhiwo se-lining ye-insulation boxes iyona nto ikhethekileyo yolu hlobo lweebhokisi ze-insulation.

Intshayelelo kulwakhiwo olupheleleyo lwefayibha ye-slab (i-ingot yentsimbi) ukuhanjiswa okushushu kweebhokisi zokugquma iimoto

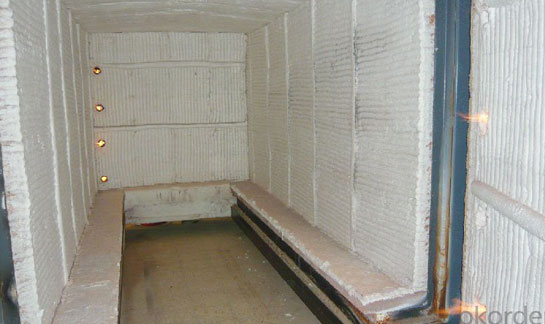

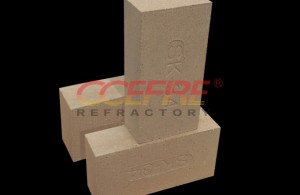

Iinkcukacha zeebhokisi zokugquma ziziitoni ezingama-40 kunye neetoni ezili-15, kwaye ubume bebhokisi yokugquma kwiitoni ezingama-40 zenqwelwana yi-6000 mm ubude, 3248 mm ububanzi, kunye ne-2000 mm ukuphakama. I-bottom of the box lining structure yi-CCEFIRE yobumba izitena zodongwe, kunye ne-CCEWOOL iimodyuli eziqhelekileyo ze-ceramic fiber ezicwangciswe ngokulandelelana kunye nolwalathiso lokusonga kwiindonga kunye nesigqubuthelo esiphezulu. Imivalo yembuyekezo yongezwa phakathi komqolo ngamnye ukuhlawulela i-shrinkage yomgca weemodyuli phantsi kokushisa okuphezulu. Imodyuli yokwakhiwa kwe-anchoring ikwimo ye-anchoring ye-nail.

Iziphumo zesicelo

Uvavanyo oluqhutywe kwesi sakhiwo lubonisa ukuba ukushisa kwe-ingot yensimbi yi-900-950 ℃, ubushushu be-ingot yensimbi emva kokulayisha malunga ne-850 ℃, kunye nokushisa kwe-ingot yensimbi emva kokukhulula i-700-800 ℃. Phakathi kokudiliza i-ingot yensimbi kunye nokuhanjiswa kwi-workshop yokukhwabanisa iikhilomitha ezi-3, kwaye ukuhanjiswa okutshisayo kuthatha malunga neeyure ze-1.5-2, apho iiyure ze-0.5-0.7 zokulayisha, iiyure ze-0.5-0.7 endleleni kunye neeyure ze-0.5-0.7 zokukhulula. Ubushushu be-ambient yi-14℃, iqondo lobushushu ngaphakathi kwebhokisi limalunga ne-800℃, kwaye ubushushu bomphezulu we-cover yi-20℃, ngoko ke isiphumo sokugcina ubushushu silungile.

1. Isithuthi se-insulation sihamba, siguquguqukayo, sisebenza kakuhle kwi-insulation, kwaye siguquguquka ngokubanzi, ngoko ke sikufanelekele kakhulu ukunyuswa kwaye sisetyenziswe kwimeko yothutho lukaloliwe olungahambi kakuhle.

2. Ibhokisi ye-fiber egcweleyo ye-thermal insulation kunye ne-red-hot delivery steel ingot (i-slab (i-ingot yensimbi)) iphumelele ngenxa yesakhiwo sayo esincinci, ubunzima obulula, ukusebenza kakuhle kwe-thermal insulation, kunye nemiphumo ebalulekileyo yokonga amandla.

3. Ukuqinisekisa umgangatho weemveliso ze-ceramic fiber kubalulekile kumgangatho wokwakha, kwaye ulwakhiwo lwe-lining kufuneka lube luncinci kwaye lube lukhuni ngexesha lokwakha.

Ngamafutshane, ukuhanjiswa okubomvu okutshisayo kwee-ingots zetsimbi (i-slabs (i-ingots zensimbi)) ngebhokisi ye-insulation ye-automobile yindlela esebenzayo kunye nebalulekileyo yokugcina amandla.

Ixesha lokuposa: May-10-2021