Idizayini yokulungiswa kabusha kwe-ceramic fibre thermal insulation box of the insulation boxes in steel ingots' (slab (ingot yensimbi)) ezimotweni ezishisayo zokulethwa

Ukwethulwa kwamabhokisi okufaka ama-ingots' (i-slab (ingot yensimbi)) ezimotweni ezishisayo zokulethwa:

Ngenxa yenqubo enzima yokukhiqiza yamabhizinisi ensimbi, ukuthuthwa kwama-slabs (ingothi zensimbi) phakathi kwe-slab (ingot yensimbi) yokuncibilikisa kanye nezinqubo zokubumba eziginqikayo kunciphisa kakhulu izindleko zokukhiqiza. Ukuze kuncishiswe ukusetshenziswa kwamandla ngokwezinga elikhulu futhi kufinyelelwe umgomo wokunciphisa izindleko zokukhiqiza, amabhizinisi amaningi okukhiqiza i-metallurgical asebenzisa izimoto ezishisayo ze-slab (ingot yensimbi) (eyaziwa nangokuthi i-slab noma i-ingot ye-ingot red-hot delivery). Ngaphansi kwezimo ezinjalo, ukugcinwa kokushisa kwebhokisi lokuthutha kube yinkinga ebaluleke kakhulu.

Izidingo zenqubo yesakhiwo se-lining yebhokisi elijwayelekile lokufakelwa kwezimoto zokuthutha ngokuyinhloko zihlanganisa izici ezilandelayo: okokuqala, umsebenzi wesikhathi eside ngaphansi kwezinga lokushisa eliphakeme lika-1000 ℃, ukusebenza kahle kokufakwa kwe-insulation, kanye nokumelana nokushaqeka okuhle kakhulu kokushisa kufanele kuqinisekiswe; okwesibili, ukulayishwa nokukhishwa kwama-slabs ashisayo (i-ingots yensimbi) ukuphakamisa kufanele kube lula, okungamelana nokudlidliza, imithelela, ama-bumps; futhi okokugcina, amabhokisi e-insulation kumele abe nesakhiwo esilula, impilo ende yesevisi, kanye nezindleko eziphansi.

Ukungalungi kolayini bezitini ezikhanyayo zendabuko: izitini ezilula azikwazi ukumelana nokushaqeka okushisayo, futhi zijwayele ukuqhuma umonakalo ngesikhathi sokudlidliza, imithelela, namaqhuqhuva.

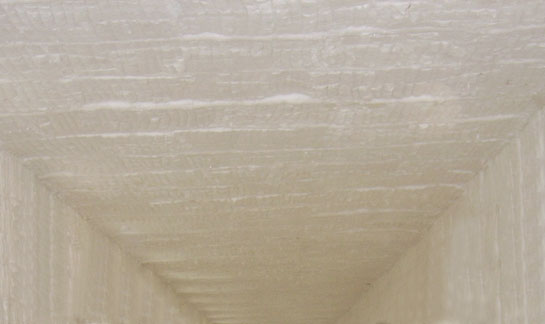

Ukuthuthukiswa kanye nokuthuthukiswa kobuchwepheshe be-ceramic fiber kunikeza isisekelo esithembekile sokwakhiwa kwamabhokisi okufakwa kwezimoto. I-CCEWOOL i-ceramic fiber ilula, iguquguquka, imelana nezinga lokushisa eliphezulu nokukhathala okushisayo, futhi ingakwazi ukumunca ukudlidliza. Uma nje ukwakheka kwesakhiwo kunengqondo, ikhwalithi yokwakha ingatholakala, futhi izidingo zenqubo engenhla zingagcwaliswa ngokugcwele. Ngakho-ke, ukusetshenziswa kwe-CCEWOOL ye-ceramic fiber njengesakhiwo somugqa wamabhokisi okufakwayo kuyisinqumo esingcono kakhulu salolu hlobo lwamabhokisi okufakwayo.

Isethulo sesakhiwo se-fiber egcwele ye-slab (ingot yensimbi) amabhokisi okufakwa okushisayo okuletha imoto

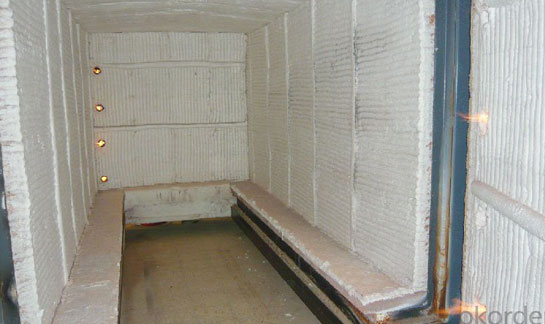

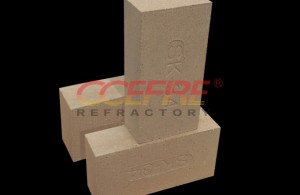

Imininingwane yamabhokisi okufakwayo ikakhulukazi amathani angama-40 namathani ayi-15, futhi ukwakheka kwebhokisi lokufakwa kwe-insulation letrailer elingamathani angama-40 lingama-6000 mm ubude, 3248 mm ububanzi, kanye no-2000 mm ukuphakama. Indawo ephansi yesakhiwo sebhokisi i-CCEFIRE izitini zobumba zobumba, ezinamamojula ajwayelekile we-CCEWOOL e-ceramic fiber ahlelwe ngokulandelana eceleni kwendlela yokugoqa ezindongeni kanye nesembozo esiphezulu. Imigoqo yesinxephezelo iyengezwa phakathi komugqa ngamunye ukuze kunxeshezelwe ukuncipha komugqa wamamojula ngaphansi kwamazinga okushisa aphezulu. Isakhiwo se-anchoring semojula sisesimweni se-nail anchoring.

Imiphumela yohlelo lokusebenza

Ukuhlolwa kokuhlolwa kwalesi sakhiwo kubonisa ukuthi izinga lokushisa lokudiliza lensimbi liyi-900-950℃, izinga lokushisa lensimbi ngemva kokulayisha licishe libe ngu-850 ℃, futhi izinga lokushisa lensimbi ngemva kokulayishwa lingama-700-800℃. Phakathi kokudiliza ingot yensimbi kanye nokulethwa endaweni yokusebenzela yokubumba kungamakhilomitha angu-3, futhi ukulethwa okushisayo kuthatha cishe amahora angu-1.5-2, lapho amahora angu-0.5-0.7 okulayisha, amahora angu-0.5-0.7 endleleni kanye namahora angu-0.5-0.7 wokuthulula. Izinga lokushisa le-ambient lingu-14 ℃, izinga lokushisa ngaphakathi kwebhokisi lilinganiselwa ku-800℃, kanti izinga lokushisa elingaphezulu lekhava elingaphezulu lingu-20℃, ngakho-ke umphumela wokulondoloza ukushisa muhle.

1. Imoto yokuvikela i-insulation iyahamba, iyagobeka, iyasebenza ekukhokhweni, futhi iguquguquka kabanzi, ngakho-ke ifaneleka kakhulu ukukhushulelwa futhi isetshenziswe esimweni sokungahambi kahle kwezinto zokuhamba zikaloliwe.

2. Ibhokisi le-full-fiber thermal insulation box kanye nensimbi yokulethwa kwe-red-hot (i-slab (i-ingot yensimbi)) iphumelele ngenxa yesakhiwo sayo esihlangene, isisindo esilula, ukusebenza kahle kwe-thermal insulation, kanye nemiphumela ebalulekile yokonga amandla.

3. Ukuqinisekisa ikhwalithi yemikhiqizo ye-ceramic fiber ibalulekile kwikhwalithi yokwakha, futhi isakhiwo se-lining kufanele sibe sihlangene futhi siminyene ngesikhathi sokwakhiwa.

Ngamafuphi, ukulethwa okubomvu okushisayo kweziyingo zensimbi (ama-slabs (ama-ingots ensimbi)) ngebhokisi le-insulation yezimoto kuyindlela ephumelelayo nebalulekile yokonga amandla.

Isikhathi sokuthumela: May-10-2021